.jpg)

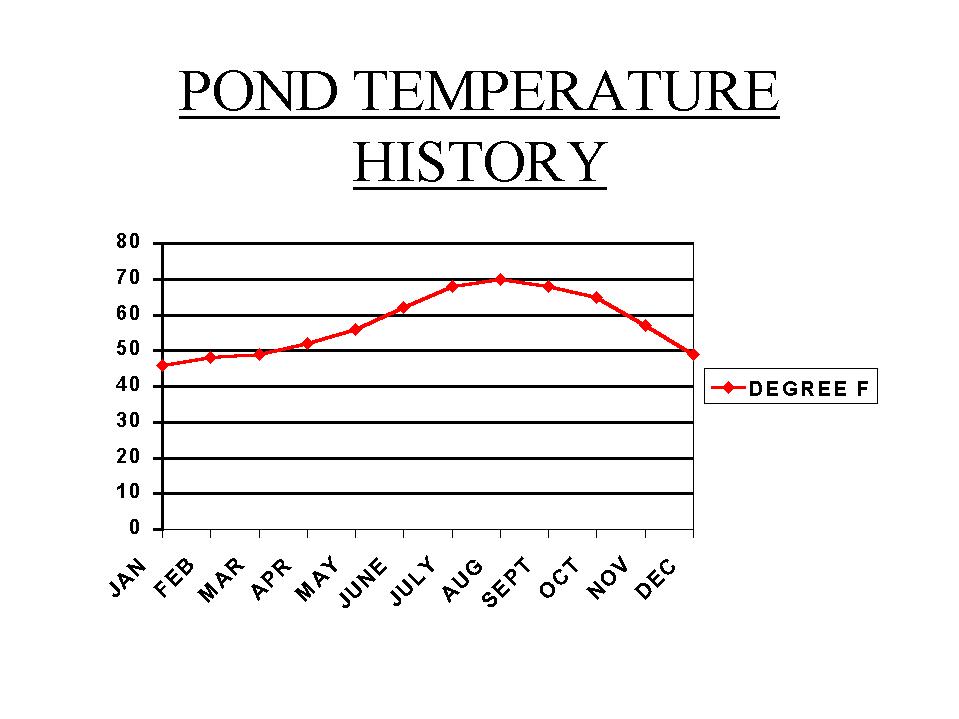

A study of Figure I shows the following:

Over Coming Aeromonas Alley

Published: By Luther C. Chien

Published: By Luther C. ChienEvery hobbyist knows that Spring is a critical time for koi. Often the koi

get sick grow ulcers, develop fin rot and die. After a long winter of fasting,

the fish are naturally weak and immunilogically stressed. Fish, like reptiles,

are cold blooded animals that rely totally on their environment to function. As

the temperature warms up, the fish are slowly adapting to their new

environmental conditions. Preying parasites and Aeromonas bacteria are growing

rapidly, and the stressed fish become their helpless victims. Why then, don't

the fish suffer the same consequences in the fall when they are exposed to the

same temperature ranges? I believe the reason is that the fish have been

building up their immunity all Summer and are at the peak of health so they are

better conditioned to fight off diseases, besides, the biofilter are also at

their optimum, so the water conditions are at their highest quality. Reference

12 supports my theory, in that it finds, once carp have been immunized at a

higher temperature (77°F), they can respond better immunilogically to lower

temperatures (50°F), and also possess immunological memory. My studies over a

two year period reaffirm the hypothesis, that pond temperature plays a critical

role in the health, growth, and immunity to disease. Even with ideal water

conditions, the fish can still get sick. Especially if, they carry traces of the

Aeromonas bacteria in their internal systems, and the temperature of the water

favors the undesirable bacteria instead of the fish. I have developed a cross

plot that illustrates my point in Figure 1. The data is based on References (10,

11,12 13 ) and contributions of D Pakiser and L Jepson References (2.9)

.jpg)

A study of Figure I shows the following:

Aeromonas bacteria are basically inactive at 40°F.Their activity increases

exponentially with every degree rise, culminating at the maximum activity at

60°F.

Koi start building immunity only after 55°F.One researcher found no white blood

cells below 55°F.The optimum temperature for carp is stated to be 77°F.

NOTE: Carp will die once exposed to 95°F.

Activity of the biofilter is also temperature dependent. The activity of Nitrobacter (the bacteria that converts ammonia to nitrites) , is non existent at 40°F. It rises to only 50% activity at 60°F.It is fully active at 75°F.The Nitrosomonas bacteria (the bacteria that converts nitrite to nitrates) is not active until 60°F.

In summary, within temperature ranges of 47°F to 62°F the Aeromonas bacteria run rampant while the fish are barely beginning to reestablish their immunities. To compound these undesirable conditions, the biofilter are only marginally active. As a consequence, ammonia and nitrites are both likely to be above the desirable range. This temperature range that is hazardous to fish is commonly referred to by the pros as the "Aeromonas Alley".

|

The sixty four dollar question is; how does one avoid the Aeromonas alley temperature range this Spring? I had several choices; 1. Cut the feed to the fish drastically for the entire spring. I rejected this option, because I could starve my fish, thus defeating my objectives, as well as, slow down the growth of the biofilter. 2. Add Amquel as needed. I rejected this option as too expensive as well as a poor long term solution. 3. Vaccinate each fish. After reading about the huge effort expended by others to net each fish and then inject them, I decided against this alternative because I had no help, and I felt it was too expensive, and I was fearful of damaging my fish and subjecting them to further stress. 4. Use other means to kill the Aeromonas bacteria. By using oxy-generators now on the market known as (OxyClear, Nature Plus). I had worked with an OxyClear unit last year and learned how to operate it with success. Over a 3 month period, I found it did, indeed, remove all traces of ammonia and all kinds of bacteria, including the active bacteria that the biofilter requires to function. NOTE: I found it was tricky to balance oxy-generators with my filtration system so that I could benefit from it, without destroying my biofilter. But, that is another story which I will discuss in a future article. In any event, I rejected this option, because, I believed that removing the Aeromonas from the water would have little or no effect on sick fish, that already carried the infectious disease internally. In fact, last year I did have a sick fish even while operating the oxy-generator device. 5. Feed treated fish food with antibiotics or immunity boosting chemicals. I did not favor this option, because, the sick and stressed fish might not eat or ingest the treated food. How then did I overcome this systemic puzzle? This year, after studying the 1997 data in Figure II and the curves in Figure I, I came to the conclusion that the best solution was to minimize the time my pond was in the Aeromonas alley temperature range. I reasoned that the fish could withstand a 15°F to 20°F temperature rise, provided, I could accomplish the increase within a week. The key was to raise the temperature at a rate, which would not stress the fish. I finally arrived at a plan to raise the temperature, 1 to 2 degrees each day. To accomplish these objectives, I had to install a heater to control my pond temperature.

|

|

| After solving the temperature question, the next question is how much feed should one start with? Feed is needed to build fish immunity and produce ammonia to grow the Nitrobacter in the biofilter. Overfeeding will surely result in undesirable ammonia levels, especially if, the biofilter are not yet fully active. The way I arrived at a satisfactory solution, was to assume that the filters were totally inactive, and then, calculate the minimum feed for a week, so as, not to exceed the maximum tolerable level of ammonia. Having calculated the acceptable amount, I then proceeded to feed that amount over a week, while monitoring ammonia and nitrite levels. I followed this plan and had no problems, so I continued the same program the second week. The third week I reasoned that the biofilter were probably operative, and increased feed on demand while still monitoring the water. | |

|

Here is how I calculated the minimum feed level; Max Tolerable Ammonia = Food Fed x Ammonia Generated per Lb. Volume of Pond 0.08=Food Fed x 1,000 x 14/454 Solving for food fed gives; *0.26 x 1,000 x 14* |

|

|

Now I would like to describe the heater system I used to control my

pond temperatures. After considerable thought, I chose to use a hot

water circulation system. It was not only simple, but easy to install,

and maintain. The heat exchanger manufacturer offers the following method to determine the heating requirements; Heat Loss (BTU/HR) = 12 x Pond Surface (square ft) x (Pond T-Outside T) Assume a pond of 3,000 gal. With a surface of 100 square ft Desired pond T of 65F and outside T of 45F,then the calculation follows; Heat Loss = 12 x 100 x ( 65-45) =24,000 BTU/HR This is the heat required to maintain the desired temperature Now if you desire to heat the pond at a rate of 1F per hr., then , you need to add additional heat calculated as follows; Heat Gain = Lbs of Water in Pond x Heat Capacity of Water For the same pond this equation becomes; Heat Gain = 3,000 gal x 8.3 lb/gal x 1 BTU/lb/HR =24,900 BTU/HR The boiler needed to do both jobs is the sum of the two requirements or; 24,900 +24,000 = 48,900 BTU/HR. On the other hand if you only wish to raise the pond temperature by only 1F per day then the total requirements become ; 24,900/24 + 24000 =1,400+ 24,000 = only 25,400 BTU/HR! For my 10,000 gal pond, I only needed a 40,000 BTU/HR hot water heater , which I bought for $140 at Home Depot. The heat exchanger needed was only one square foot.(the smallest heat exchanger I could buy ). In conclusion: I advocate installation of a heater in your pond to control temperatures in the spring , I am not advocating maintaining high temperatures all winter long. Controlling temperatures in fish tanks is not new, it is routinely practiced by all who raise tropical fish. Koi are mistakenly grouped with goldfish and carp and most new hobbyists think koi can endure anything.. The fact of the matter is , that koi are unique, they are highly interbred and as a result , genetically weak. We must treat our koi with tender loving care! TAKE STEPS NOW, TO CONTROL YOUR POND TEMPERATURES! Avoid the disastrous effects of unanticipated temperature swings next Spring! Healthy koi need a STABLE ENVIRONMENT outside the AEROMONAS ALLEY! References for this article gathered from: 1. Aquatic Eco Systems Sales Catalogue,1998, p(373) 2. Winterizing Your Pond; D Pakiser, Koi USA,Vol.22,Issue 2 p (62) 3. Beginners Class, F Prince-Lies, Koi Health Quarterly,Issue12,p (15-17) 4. Health or Disease-It. s a Fine Balance , T Roberts, Koi Health Quarterly Issue 6 ,p (7) 5. Heating Your Pond, N Guedalia, Mid Atlantis koi, March 1997,p (39-410 6. Efficient Koi Water Heating Using Your Gas Water Heater, L Lunsford. Mid Atlantic Koi,Nov-Dec,1996 p (28-30) 7. Koi Health and Disease, Erik l Johnson DVM 1997, p (137) 8. Body Ulcers in Koi, Erik l Johnson DVM ,Koi Health Quarterly, Issue 9 p(9) 9. Thermoregulation in Koi ,L Jepson, Koi Health Quarterly, Issue 15 p (36) 10. Immune System of Cyprinid Fish; Kinetics and Temperature Dependence of Antibody Producing Cells in Carp, G T Rijkers, E H Federix-Wolters,&W B Van Muiswinkel , Immunology 41, p (91-97) 11. Minimum Water Activity for Growth of Aeromonas-Hydrophilia as Effected by Strain Temperature and Humectant, J Santos, M Lopez, M C Garcia Fernandez, A Otero ,Letters in Applied Microbiology,1994,Issue 2 p (76-78) 12. Comparative Immunology , Edwin L Cooper,p (241-245) 13. Temperature Effect on Antibody Production and Immunological Memory of Carp, R R Avtalion, Immunology, 1996, 17 p (927) 14. Preferred Temperatures for Some Invertebrate Ectotherms ,Chapter 5 , p (134) Comparative Animal Physiology, A Withers,1992. |

|

Edited for this publication by: William Risher